You require a Mt. Vernon GC who knows historic homes, narrow-street logistics, and freeze‑thaw durability. Expect centralized accountability, clean permits, coordinated MEP, and inspection-ready work. Demand honest, itemized bids tied to CSI divisions, clear schedules with critical-path tracking, and documented change procedures. Verify licensing, insurance, references, and safety plans. Insist on in-person evaluation to confirm access, staging, hidden conditions, and communication fit. Choose the contractor who shows competence, transparency, and risk control—what follows shows how to confirm it.

Main Points

- Local Mount Vernon experts in historic homes, infill, and complex neighborhood regulations, including Historic Commission reviews and narrow-street logistics.

- Unified accountability from preconstruction through closeout with standards-compliant permitting, aligned timelines, and readiness for inspections.

- Transparent, line-item proposals mapped to CSI divisions with allowances, contingencies, lead times, and alternates explicitly outlined.

- Proactive risk and schedule management using critical-path tracking, look-aheads, resource leveling, and documented change-order procedures.

- Checked licensing, bonding, insurance, local references, and clear communication protocols with documented sessions, RFIs, submittals, and daily reports.

Why Regional Expertise in Mount Vernon Matters

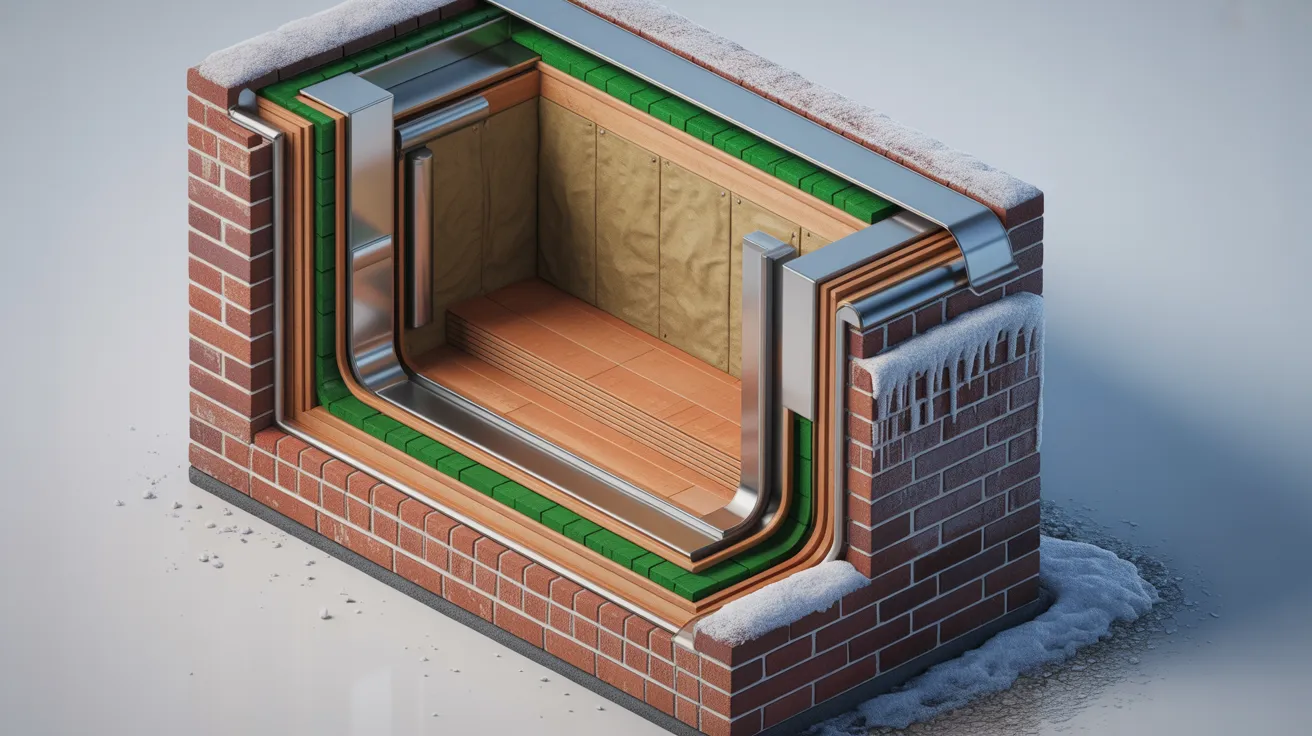

In Mount Vernon's unique mix of historic homes and new infill, regional knowledge isn't a bonus-it's required. You work through complex historical contexts, tight setbacks, and shifting community requirements while avoiding setbacks or revisions. You understand which materials endure the local climate, when to time exterior work to sidestep freeze-thaw cycles, and how to safeguard stone, slate, or timber cladding during updates.

You coordinate permits efficiently, anticipate historical review requirements, and sequence trades to minimize disruptions on narrow streets. You source code-compliant products that match legacy aesthetics, align mechanical upgrades with existing envelopes, and prevent moisture intrusion in basements common to the area. You also vet subcontractors familiar with Mount Vernon's inspection protocols, ensuring documentation, safety, and workmanship meet or exceed standards the first time.

Key Services to Expect From a General Contractor

Looking at the big picture, you should expect a general contractor to serve as the single point of accountability-from preconstruction planning through closeout. You'll get code-compliant permitting, accurate scopes, and coordinated schedules. They take care of site surveys, utility locates, and site preparation waste disposal in accordance with local ordinances. You can rely on rigorous material selection that meets specifications, durability targets, and warranty requirements.

Your contractor oversees structural framework, MEP coordination, and weatherproofing, confirming inspections pass on the first call. They install energy efficiency elements-air sealing, insulation R-values, high-performance windows, and correctly sized HVAC. Expect moisture management, firestopping, and compliant egress solutions. Interiors are executed with precision: drywall, tile, millwork, and finish carpentry aligned to plans. Ultimately, they execute punch-list resolution, O&M documentation, and thorough turnover.

How Exactly Reputable Contractors Protect Your Financial Plan and Schedule

You protect costs and time when your contractor delivers transparent, itemized bids that align scope with code-required materials and labor. They handle the schedule proactively with critical path tracking, permit coordination, and real-time updates. They also integrate risk and contingency planning into the contract by allocating allowances, buffers, and escalation protocols—so surprises don't derail your budget or timeline.

Transparent, Detailed Bids

Commonly underestimated but vitally necessary, transparent, itemized bids protect your budget and schedule by breaking every scope line into clear labor, materials, allowances, and contingencies with predetermined quantities and unit costs. You obtain a line item breakdown that connects each task to CSI divisions, specified products, and measurable quantities, so you can confirm scope and compare apples to apples. We establish material sourcing transparency with specified suppliers, lead times, unit pricing, and alternates that meet code and manufacturer requirements.

Each allowance states finish levels, mounting procedures, and quality benchmarks, minimizing change orders. Contingencies are right-sized and tied to identified risks, not vague extras. Overhead and profit are transparently divided. You greenlight substitutions in writing. This clarity lets you control scope, verify pricing, and authorize work with confidence.

Forward-Thinking Schedule Control

Intentional work sequencing maintains your project's timeline and budget. A comprehensive build schedule is provided that establishes critical routes, worker assignments, and inspection schedules, coordinated with code-mandated checkpoints. We utilize progress tracking to assess actual advancement versus estimated timelines, then adapt each day to ensure trades continue without inactive periods.

You'll observe look-ahead schedules that secure material lead times to installation windows. Resource leveling balances labor, equipment, and deliveries so crews aren't overburdened or idle, cutting overtime and rework. Submittals, permits, and utility coordination are scheduled early, so approvals occur prior to mobilization. We check measurements, shop drawings, and field conditions before release, eliminating costly resequencing. With systematic updates, documented constraints, and clear dependencies, you keep informed, invoices correspond to progress, and the finish date remains dependable.

Risk and Contingency Planning

With timelines confirmed and teams synchronized, the next safeguard is a formal risk register and contingency plan that protects financial and timeline parameters. You'll see every foreseeable threat documented, rated in a risk matrix by probability and severity, and tied to a specific owner. We calculate exposure, set triggers, and predetermine responses so decisions aren't improvised under pressure.

We set up contingency reserves coordinated with your budget and schedule float, then separate them from scope growth to preserve accountability clear. Critical-path materials get alternate suppliers, weather-sensitive work receives sequencing buffers, and code inspections are reserved ahead with corrective paths documented. Monthly reviews recalibrate risks, burn-downs, and remaining reserves. When an issue emerges, you get swift execution, transparent change documentation, and a controlled return to baseline targets.

Permits, Building Codes, and Inspections: Understanding Compliance Requirements

Before any demolition or framing begins, you need a well-defined strategy for permits, code compliance, and inspections to keep your project legal, safe, and on schedule. You'll confirm the scope, submit complete building permits, and coordinate with the city to align inspection timelines with your critical path. Establish structural, electrical, plumbing, and energy code requirements, then detail them in stamped drawings.

Remain informed on code updates that influence egress, fire blocking, load paths, and mechanical ventilation. Create a checklist for rough-in, insulation, and final inspections, and stage the site for unobstructed access and documentation. Preserve compliance documentation: approved plans, correction notices, product submittals, anchorage records, and photos. Wrap up permits quickly, archive revisions, and keep as-builts correct-so your final inspection passes the first time.

Correspondence, Agreements, and Project Changes Handled Correctly

Even as scopes change and schedules compress, you ensure success with well-defined communication protocols and ironclad contracts that define roles, deliverables, and decision rights. You establish precise expectations from day one: scope, requirements, schedule milestones, payment terms, and closeout procedures. You document meeting cadences, points of contact, and response times to keep client communication focused and traceable.

You require written scopes and drawings to align with code and manufacturer standards, and you verify conflicts before work starts. For changes, you issue formal change documentation: scope narrative, cost breakdown, schedule impact, and dependencies. You don’t proceed without documented approvals—signed, dated, and linked to revised drawings. You track RFIs, submittals, and daily reports, maintaining a single source of truth. With disciplined records, disputes shrink and delivery stays predictable.

Guide to Vetting and Selecting the Best Contractor for Your Project

Start by defining what "best" means for your scope, budget, and schedule, then check each prospect against objective criteria. Verify an active Mt. Vernon business license, bonded status, and general liability coverage and workers' compensation. Check current contractor registration and disciplinary record. Request a written scope, line-item estimate, schedule, and warranty terms.

Perform a rigorous references check: call past clients, request project photos, and ask about completion checklist completion and cost control. Review portfolio suitability to your project type and code knowledge. Evaluate communication promptness, clarity, and change-order process. Meet at the property to assess personality fit and problem-solving capabilities. Compare bids for completeness, allowances, and exclusions. Emphasize safety measures, permitting strategy, and inspection readiness. Choose the contractor who shows competence, transparency, and reliability.

Frequently Asked Questions

Can Contractors Provide Design-Build or Partner With Architects You Select?

Absolutely. Numerous contractors provide a complete design build service, guiding you from initial ideas to permits and construction. If you already have a designer, they'll enable architect collaboration, managing drawings, specifications, and code compliance. You'll receive budgeting, value engineering, and constructability reviews in the initial stages, decreasing change orders. They'll oversee consultants, approvals, and inspections, coordinate schedules, and maintain clear documentation, so your selected architect's vision integrates seamlessly with accurate pricing, timelines, and quality control.

What Types of Warranties and After-Completion Support Are Usually Offered?

About 63% of homeowners indicate better outcomes when projects include documented warranties. You generally receive twelve-month workmanship coverage, manufacturer product warranties tied to installation, and code-compliant structural warranties spanning 5 to 10 years. Warranty agreements should list response times, exclusions, and transferability. You also obtain punch-list completion, closeout documents, and optional maintenance plans for seasonal inspections, sealant renewal, and system tune-ups. Ensure a single point of contact, clear escalation processes, and written service logs.

How Do We Select, Vet, and Supervise Subcontractors On-Site?

You choose subcontractors through prequalification: verify licenses, insurance, and safety records, then run licensed background checks. You assess trade specific references, recent project portfolios, and EMR/OSHA logs. You issue detailed scopes, code-compliant specs, and QA checklists. On-site, you facilitate orientation, check permits, and implement PPE and toolbox talks. You manage with daily reports, progress inspections, and hold points, leveraging schedules and RFIs to oversee coordination, fix deficiencies, and document performance.

What Cost-Effective Sustainable or Energy-Efficient Options Can Be Integrated?

You can integrate budget-friendly sustainability by transitioning to LED lighting, incorporating smart thermostats, boosting insulation and air sealing, and specifying low-flow fixtures. Implement tankless water heaters for instant efficiency and space savings. Choose Energy Star appliances, variable-speed HVAC, and balanced ventilation (ERV/HRV) to comply with code and enhance IAQ. Select cool or reflective roofing and solar-ready conduit. Focus on blower-door testing, duct sealing, and right-sized equipment to ensure measurable, here code-compliant performance.

How Are Dust, Noise, and Site Safety Managed During Construction?

You control dust via source capture, negative-pressure containment, and HEPA air filtration, plus damp sweeping and sealed debris chutes. You handle noise using scheduling, equipment maintenance, and noise abatement measures such as barriers and acoustical blankets. You copyright site safety with OSHA-compliant PPE, daily JHAs, clear egress paths, guardrails, lockout/tagout, and NFPA-compliant hot work permits. You post signage, secure perimeters, perform toolbox talks, and document inspections to validate code compliance throughout construction.

To Conclude

You're poised to shift plans into momentum. Partnering with a Mount Vernon contractor who understands local codes, timelines, and inspectors, your project won't wander-it'll move like a train on schedule. Expect clear scopes, airtight contracts, transparent change orders, and documented milestones that protect your budget. Validate licenses, insurance, references, and past work, then establish communication and quality standards before you sign. Select carefully, and you'll construct once, construct correctly, and construct by code-without surprises compromising your investment.